Pressure Relief Valve (pictured right)

Is designed for relief of excess pressure, usually 15-25% above the system operating pressure. Its main purpose is to protect the pressure vessel, pump, pipes, valves and other equipment from damage by excess pressure. Once the set pressure is reached, the valve opens to evacuate the media and will reseat again once the pressure has been relieved. It is recommended that the valve is inspected after each blow-off to ensure correct re-seating and operation. In many designs, the discharge port is at right angles to the inlet and is often larger than the inlet size, thus assisting rapid discharge of the product.

If there is a need for frequent operation, this is not the correct valve to use and a back pressure valve (as pictured below) is the better selection.

Safety Valves used on compressible media (steam, air etc) often have a specially designed disc profile to assist in rapid valve lift and less overpressure. They usually have a lifting lever to manually lift the disc, thus confirming operation and to assist clearing debris or scale from the seat and disc.

Correct sizing is essential for proper operation.

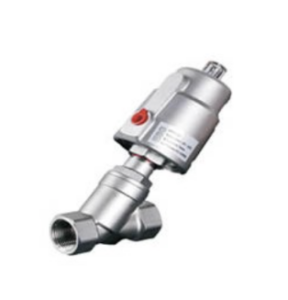

Pressure Sustaining (or Back Pressure) Valve (Jordan Mk50 & JBPH pictured above)

Can be used in several ways and is commonly used to maintain the upstream pressure in a ring main or piping system. In a typical installation, it is installed in a “tee” off the main line where it remains closed until the set pressure is reached. Although it opens at a predetermined setting like the relief valve, it does not necessarily discharge at full capacity. Rather, it only opens far enough to relieve the excess pressure and can modulate and operate 24 hours a day, if necessary. They are commonly found on boiler feedwater lines where they allow the pumps to keep pumping and bypassing back to the tank when the boiler is full. This saves wear & tear on the pump and guarantees that the boiler will not be starved on water when it needs to be replenished. Another application could be to guarantee the pressure in an essential service (eg eyewash, deluge shower or even regions in the case of urban water supply applications) by ensuring that other ancillary lines are only pressurised when there is ample excess pressure above the minimum required by the priority line.

Correct sizing is essential for proper operation.